Flames——适用于功能层的测量系统

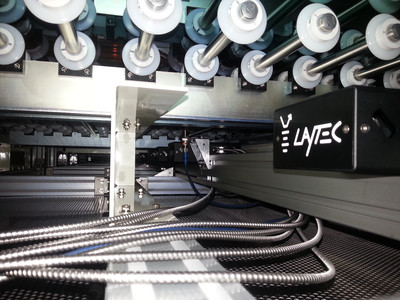

雷泰的Flames系统是一套多头光学测量系统,适用于监测大面积制程中的多层薄膜结构。该系统可在完成生产线沉积制程后,在多轨迹下直接测量层厚度、反射率、透射率和均匀性,厚度分辨率小于1nm。通常适用于显示屏行业、箔涂层(卷对卷)和玻璃涂层。Flames几乎适用于任何薄膜生产线。该系统采用无接触光学法测量制程,对层沉积和蚀刻进行封闭式控制。在使用雷泰Flames系统时,用户可根据生产线的单件生产速度,在完成制程后直接获取各层的同质性信息,完成统计分析。用户可设置质量阈值和警报,便于操作人员快速反应。

Antireflective coatings on solar glass

In order to minimize efficiency losses due to reflection of sun light on the front glass of PV modules, high-end solar glass is often equipped with an antireflective coating. The coating is deposited as a liquid by spray-coating or by printing techniques. Thereafter it is dried and annealed in consecutive production steps. The properties of the coating must be optimized in a way that the minimum of the reflectance matches the spectral absorption and conversion efficiency of the solar cells. Hence, spectral reflectance measurements directly deliver the most relevant information to characterize the coating in the production line. Fig. 1 shows the reflectance of uncoated glass and of glass coated by two different ARCs.

Fig. 1. Reflectance spectra of uncoated glass and of AR coated glass with reflection minima at 665 nm and 760 nm.

As the reflectance of an ARC on glass is very low (this is the very purpose of the ARC) and it is mostly deposited on rolled glass which is used in this field of application, in-line measurements are quite challenging. However, optimisation of the optical metrology system’s design allows measurements with a repetition rate of up to 100 Hz even under these conditions.

示例:显示屏生产过程中的非晶硅层测量

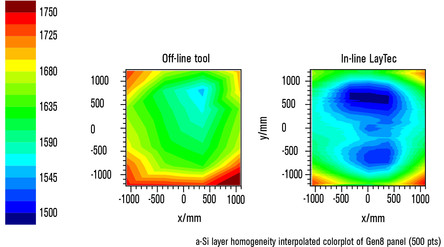

应用:在集群系统完成沉积后,生产线反射率测量可直接对非晶硅/SiO/SiN层叠的即时层进行厚度分析,其第8代玻璃面板上具有金属接触图案。 ###HIDE###系统不会对单件工时造成影响,可以便捷的集成于传送带生产线上。每个面板在各跟踪范围内可设置100个测量点。可以对整个面板尺寸进行同质化的控制和统计分析(最小值、最大值、平均值、百分比)。

TF显示屏:非晶硅功能层

雷泰公司的Flames系统可为生产控制提供高精确度的信息。系统还可跟踪交叉板的厚度波动及长期偏移。通过对面板的100%控制,可以改善平均清洁时间(MTTC)和产量。

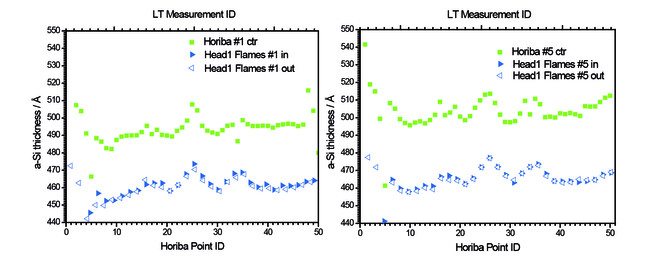

Fig. 1+2: a-Si thickness on two substrates A and B: in-line Flames is compared to ex-situ reference (Horiba)

由于折射指数较小,因此在使用其他参考椭圆仪测量非晶硅层时,得出的厚度值较大。两种测量方式均可解决厚度波动问题。可在全部衬底的即时层和覆盖层进行Flames在线测量,而其他参考方法需要耗时几分钟,仅适用于少数衬底。

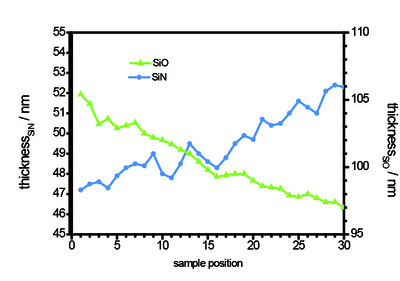

50nm非晶硅/100nm氧化硅/50nm氮化硅层叠

雷泰公司的Flames系统可为整个层叠提供纳米级的精确在线监测(如,非晶硅、SiNx、SiOx)。直接多层分析可以节约实验室分析时间,提高产品质量保证!实例表明,以及45nm非晶硅/100nm氧化硅/50nm氮化硅层叠的SiNx和SiOx和非晶硅在线测量可达到亚纳米级分辨率。

有关Flames系统优化制程的详细信息,请联系mail@laytec.de或拨打电话+49(0)30 89 00 55-0。

CdTe and CIGS based thin-film PV

Combining two Flames metrology systems of different spectral range gives access to measuring the properties and thickness of all layers throughout thin-film solar cell manufacturing processes, including transparent conducting oxide (TCO) and absorber and buffer layers. Especially, with the IR spectral range included, the position and number of interference fringes of the thick absorber layers can be automatically analyzed and fitted to determine the absorber’s film thickness on-line. By measuring the reflectance after each deposition step, the thickness of each layer can be determined with high precision.

While TCO and CdS film thicknesses are detected with a spectrometer operating in the visible to near-infrared spectral range (500–1000 nm), a determination of the film thickness of the absorber layer requires an infrared reflectance measurement, as these materials are designed to completely absorb visible light. The thickness measurement accuracy is typically 1–2 %. LayTec has built upon its extensive expertise in fitting optical data and accurately measuring optical properties (n and k values) in multi-layer processes to create the most precise automated thickness analysis available for thin-film PV.

To find out how Flames can optimize your process please contact mail@laytec.de or simply call +49(0)30 89 00 55-0.

Product information

Fields of application

- Reflectance

- Transmittance

- Layer thickness

In thin-film PV display and glass coating processes!

Download

- Application Note: In-line thickness monitoring during R2R OLED and OPV manufacturing

- Application Note: In-line monitoring of layer properties and thickness in thin-film PV processes

- Application Note: In-line roll-to-roll application

- Application Note: Flames IR for measurement on CdTe-based cells

- Flames Flyer

- Flames IR Flyer

- 火焰 Flyer

- Presentation - Company Overview and TF-Displays

- Poster - Optical in-line monitoring of deposited layers in large area coating lines

Metrology news for PV industry

- Talk at ISFOE "Industrial-scale metrology for automated in-line and in-situ quality control"

- ILMetro – in-line metrology station for CdTe based thin-film PV

- In-line metrology for ARC coating on structured PV glass

- CTF Solar chooses LayTec for new TF-PV fab in China

- Astronergy installed X Link® for in-line lamination control

- REC installed X Link® SAM

- 100% monitoring of lamination process: PV-Tech reports about X Link®

- Flexible OLEDs monitored by LayTec

- PearL qualified for CIGS monitoring in high-volume PV production

- 50 nm thin layers monitored with astonishing precision by SolR®