Fault detection and classification (FDC)

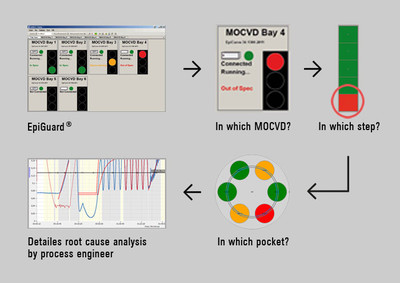

The goal of FDC is to detect abnormal behavior in either the growth system or the in-situ tool, so that the deposition run will not be started or continued. This can also include the scheduling of preventive maintenance. LayTec's EpiGuard® with the additional FAB view feature allows to keep under control several deposition systems and to detect in real time where failures or process deviations occur.

The goal of FDC is to detect abnormal behavior in either the growth system or the in-situ tool, so that the deposition run will not be started or continued. This can also include the scheduling of preventive maintenance. LayTec's EpiGuard® with the additional FAB view feature allows to keep under control several deposition systems and to detect in real time where failures or process deviations occur.

Example

A typical application of FDC is the detection of window coating. LayTec tools use the reflectance measurement capability to characterize window transparency, usually once per run on the bare substrate. High sensitivity can be achieved by using the short wavelength 405 nm reflectance. An increasing window coating will affect the accuracy and the signal-to-noise ratio of both the temperature and reflectance measurement. Therefore, early detection of increasing coating is critical. In addition, an unexpected increase of window coating can also indicate a malfunction of the purge flow of the MOCVD system.

For further information and an individual solution for your fab please contact sales@laytec.de or call +49(0)30 89 00 55-0.

Advanced process control