PearL & t-PearL

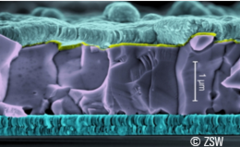

Spectroscopic photoluminescence (sPL) gives access to information on the band gap, electronic defects and the related composition of materials, e.g. the gallium / (gallium+indium) ratio (Ga/(Ga+In) ratio) and copper (Cu) content of CIGS solar cells. LayTec’s sPL has a total measurement and analysis time of only 100 ms.

Spectroscopic photoluminescence (sPL) gives access to information on the band gap, electronic defects and the related composition of materials, e.g. the gallium / (gallium+indium) ratio (Ga/(Ga+In) ratio) and copper (Cu) content of CIGS solar cells. LayTec’s sPL has a total measurement and analysis time of only 100 ms.

PearL can also be combined with t-PearL (TRPL) for comprehensive electronic characterization of thin film semiconductors. In particular, the option of vacuum integration can be very advantageous for characterizing uncompromised surfaces.

Generally, PearL and t-PearL can also be used as components in LayTec’s combined and fully integrated ILMetro in-line.

The t-PearL monitoring system analyzes the time-dependent decay of photoluminescent radiation emitted from a probed surface after excitation with laser light. Thereby it provides a direct metric for the carrier lifetime. It is designed for in-line integration in production lines or in a vacuum environment. Time-resolved photoluminescence (TRPL) gives access to information about the minority carrier lifetime and electronic defects of CIGS, CdTe, perovskite thin films and solar cells. By analyzing the superposition of several decay modes, t-PearL provides further information about the nature of recombination processes in compound semiconductors. It can resolve decay times as low as 5ns and can also be modified for longer lifetime materials such as silicon or III/Vs. LayTec’s TRPL has a total measurement and analysis time of only 100 ms.

PearL’s and t-PearL’s advantages under R&D and production conditions for thin film photovoltaics:

- Reliable CIGS, CdTe, perovskite etc. characterization at various sample positions for all relevant sample sizes – up to full module characterization.

- Spatially resolved information about band gap (PearL), material composition (PearL), lifetime (t-PearL) and quality of the thin film semiconductor material.

- Integration into LayTec’s ILMEtro combined and fully integrated metrology stations.

- Analysis of the thin film directly after its deposition without interference of other layers – optionally even without vacuum breach

- Identification of faulty samples before the time- and cost-intensive back-end processing

- Simplified root-cause analysis and minimum feedback times by direct sample assessment of uncompromised layers

- Measurement time of only 0.1 s

- Find more information and measurement data in our PDF newsletter

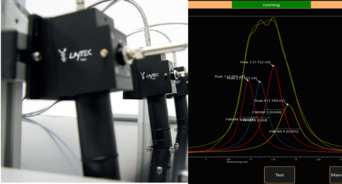

PearL and t-PearL are based on LayTec’s modular platform for in-line and in-vacuo optical set-ups. Up to three optical heads can be attached to a single PearL controller, to monitor the composition simultaneously on three traces on moving specimen. This allows accurate monitoring of the center to edge uniformity of the material composition. A controller unit contains all optical and electronic components including a real-time embedded controller for maximum reliability. Optical fibers guide the measurement light between the controller unit and the measurement positions. Miniaturized measurement heads provide optimum optical performance with a small footprint. Sophisticated automated analysis, monitoring, and storage of the data are provided by a metrology PC connected to the controller unit. In addition, PearL can also be integrated with production machines and software systems via a large variety of protocols such as OPC, Ethernet, ProfiBus, and others. Typical accuracy of the measurement at PL Peak position is ± 0.5 nm. With this resolution, the sensitivity to the Ga content for CIGS is ± 0.01 GGI, where GGI is the molar gallium/(gallium + indium) ratio.

With t-PearL lifetimes as low as 5ns can be resolved thereby enabling materials development from very low up to highest lifetimes of several hundred ns. Various algorithms also allow for superimposed decay analyses. For longer lifetime materials modified specifications can be offered upon request.

For further technical information and measurement examples please download our Application Note

To find out how PearL can optimize your CIGS process please contact info@laytec.de or simply call +49(0)30 89 00 55-0.

Product information:

Fields of application:

- Fast detection of the effective Ga content of the absorber in CIGS-based production lines

- Product version for CdTe absorbers also available

Product features

- Adaptable to every in-line process via customized optical heads and mounts

- In-line integration for 100% inspection of produced modules

- Spatially resolved spectral photoluminescence measurements through multiple heads

- Fast data acquisition for in-line measurements on moving substrates

- Up to 10 measurements per second

- Automated spectrum analysis calculation of key parameters e.g. Ga/(Ga+In) and Cu content of CIGS layers

- PV-line software integration via Profibus, Ethernet, TCP/IP or other protocols for automated operation

Product news

PearL qualified for CIGS monitoring in high-volume PV production

Downloads