Quantitative in-situ monitoring for optimization of nanowire growth

The most critical parameters for nanowires’ optical response are their length and diameter. Usually, time consuming and destructive ex-situ methods like scanning electron microscopy (SEM) are used for characterisation before further processing. But now, LayTec and the Nanometer Structure Consortium at Lund University (nmC@LU) in Sweden have jointly developed a solution for real-time quantitative monitoring of III-V nanowire growth. The team of Prof. Lars Samuelson used LayTec’s spectroscopic in-situ reflectometer EpiR to monitor nanowire epitaxy in an AIXTRON 200/4 reactor. The video below (Fig. 1) shows an MOVPE run sequence where InP shells were grown on InP core nanowires:

Fig. 1: Video of a nanowire growth run. In the color plot (left), the reflectance is given by the color. ©nmC@LU

The data of previous ex-situ analysis by SEM and spectroscopic reflectance [1] were used by Nicklas Anttu of Lund University to develop numerical algorithms for deduction of the average length and diameters of the growing nanowire ensemble. Together with these algorithms, the in-situ spectroscopic measurements by EpiR provide information on the evolution of nanowire length and diameter already during growth.

EpiR enables effective process optimization, speeds up development and paves the way to future process transfer for industrial nanowire growth. In-situ metrology will be a must in nanowire applications in the near future. For further information please contact info@laytec.de.

Nanowire benefits

Nanowires (sometimes also called nanorods) are becoming more and more attractive for next generation LED and solar cell applications. One of the reasons is the fact that epitaxial III-V nanowire arrays combine 1-dimensional electronic states with additional degrees of freedom for strain relaxation and resonant electromagnetic interaction.

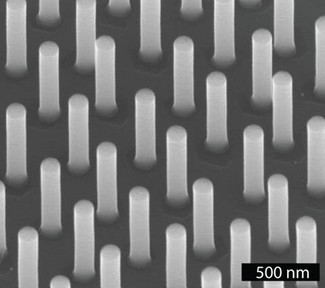

Fig. 2: SEM image of InP nano-wires structured with gold particles by nanoimprint lithography. ©nmC@LU.